Asset Tracking Excellence

intelliTRACK

Monitor every asset accurately with IoT sensors and AI-driven location intelligence. Receive instant movement alerts, automated maintenance reminders, and predictive failure notifications. Achieve zero asset loss and reduce maintenance costs by up to 50%—always know where your assets are.

Real-Time Task & Milestone Monitoring

Automated Maintenance & Assessment Management

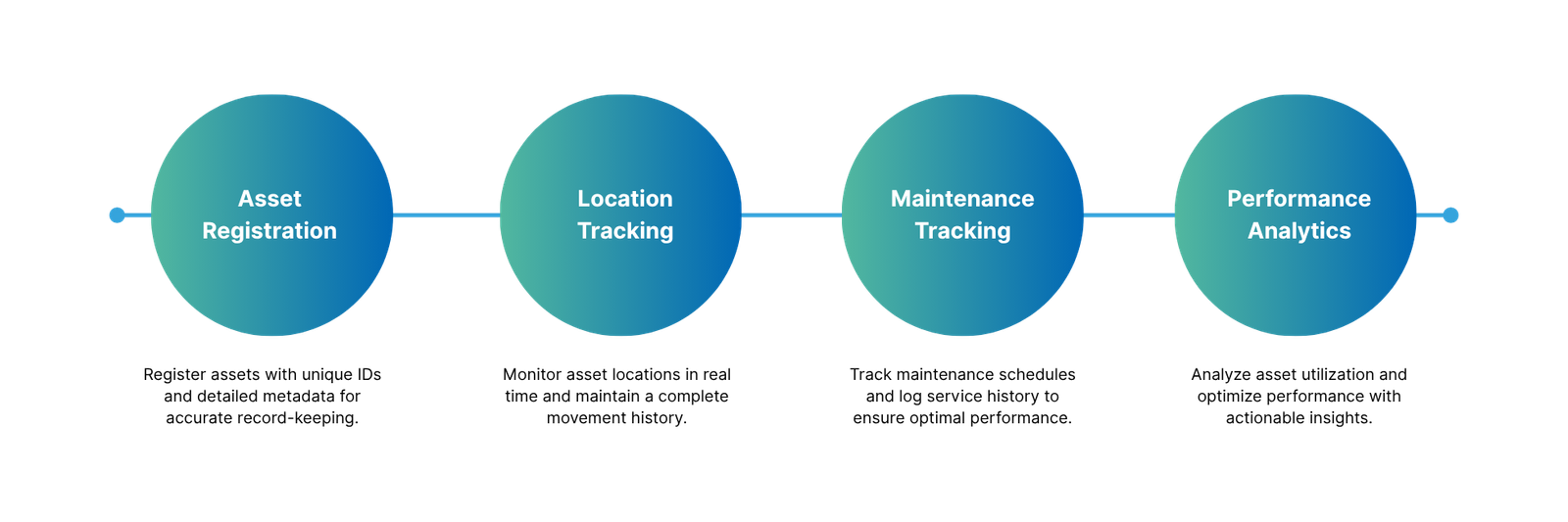

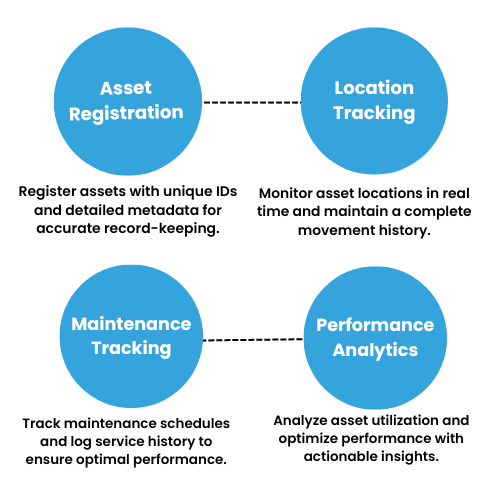

Key Features

End-to-End Workforce Management!

Equipment Checkouts

Manage equipment assignments, returns, and usage records with digital signature verification.

Inventory Logs

Monitor inventory in real time with automated alerts and low-stock notifications.

Maintenance Cycles

Plan and track preventive maintenance with automated reminders for timely upkeep.

Asset Movement History

Maintain a full audit trail of asset locations, transfers, and usage trends.

RFID & QR Code Tracking

Leverage RFID, QR codes, barcodes, and NFC for precise asset tracking.

Analytics & Reporting

Gain actionable insights with comprehensive analytics on asset utilization, costs, and performance.

Proven Excellence

Enhance turnaround efficiency with proven, quantifiable results.

Enhance operations with workforce strategies that deliver clear, trackable results.

Reduced Downtime

Cut equipment downtime by up to 50% with real-time monitoring.

Inventory Accuracy

Boost inventory accuracy to 95% with automated tracking.

Lower Maintenance Costs

Reduce maintenance expenses by 30% through predictive scheduling.

Higher Utilization

Increase overall asset utilization by 40% with smart management.

Minimized Loss

Minimize lost equipment by 80% using real-time location tracking.

Streamlined Audits

Streamline audit processes by 70% with automated reporting.

Workforce Journey

Seamless Oversight of the Entire Workforce Journey

Advanced Tracking Technology

Cutting-edge tracking solutions for full visibility and control over your assets.

The Rescue & Technician Workforce Manager

A next-generation solution for workforce optimization, offering AI-driven deployment of specialized safety personnel and comprehensive tracking of skills and certifications.

Barcode/RFID-Based Tracking

Every asset is tagged for quick mobile check-in/out, enabling complete chain of custody tracking.

Technician Assignment & Verification

Equipment is only assigned to technicians whose certifications match equipment requirements, preventing misuse.

Automated Calibration & Maintenance Reminders

System tracks calibration and maintenance dates, auto-generating alerts and work orders to ensure compliance.

AI-Powered Defect Detection

AI automatically detects and flags defects or damage during the process.

Inventory & Utilization Dashboards

Live dashboards show equipment inventory, location, and utilization to optimize fleet size and purchasing.

Usage & Maintenance History

Maintain detailed logs of usage time, maintenance schedules, and repair costs for comprehensive reporting.

FAQ (Frequently Ask Questions)

RFID, QR, bar codes, and NFC are supported for flexible identification and tracking.

Yes. You can view movements across sites with complete transfer and location history.

Yes. Capture check‑ins/outs and inspections offline; data syncs automatically later.

Automated schedules, reminders, and work order generation streamline PM programs.

Yes. API‑first integrations connect with common CMMS/ERP platforms.

RFID/QR scans, exception audits, and reconciliation workflows reach 95%+ accuracy.

Dashboards provide utilization trends, cost breakdowns, and exception alerts.

Digital signatures, user attribution, and timestamps ensure accountability.

Use existing scanners/tags where possible or choose from recommended devices.

RBAC scopes permissions by role, team, and site; all access is audited.