Asset Integrity Excellence

AI-Powered Asset Integrity, Maximum Protection

Safeguard assets with AI-driven integrity monitoring and predictive maintenance. Gain real-time corrosion insights, automated coating evaluations, and failure forecasting. Achieve up to 70% less downtime and extend asset life by 40%—protecting your investments.

Real-Time Visibility & Critical Path Monitoring

Automated Flange & Assessment Management

Key Features

Complete Asset Integrity Management Solutions!

Mechanical Health Monitoring

Real-time tracking of equipment condition, vibration, and performance metrics.

Corrosion Management

Monitor corrosion rates, identify critical points, and implement mitigation strategies.

Coating Performance Assessment

Evaluate coating condition, detect degradation, and schedule maintenance.

Fireproofing Monitoring

Ensure fireproofing integrity and compliance with safety regulations.

Predictive Maintenance Analytics

AI-driven forecasts for potential equipment failures and maintenance planning.

Asset Integrity Database

Centralized repository for all integrity data, history, and inspection records.

Proven Excellence

Enhance turnaround efficiency with proven, quantifiable results.

Achieve tangible improvements in your asset integrity management.

Minimize Unplanned Downtime

Reduce unplanned downtime by 70% to keep operations running smoothly.

Prolong Asset

Lifespan

Extend asset lifespan by 40% through proactive maintenance.

Lower Maintenance Expenses

Cut maintenance costs by 35% with optimized asset management.

Enhance Safety

Compliance

Improve safety compliance by 95% through structured monitoring.

Boost Equipment

Reliability

Increase equipment reliability by 60% using predictive insights.

Decrease Inspection Frequency

Reduce inspection frequency by 50% without compromising quality.

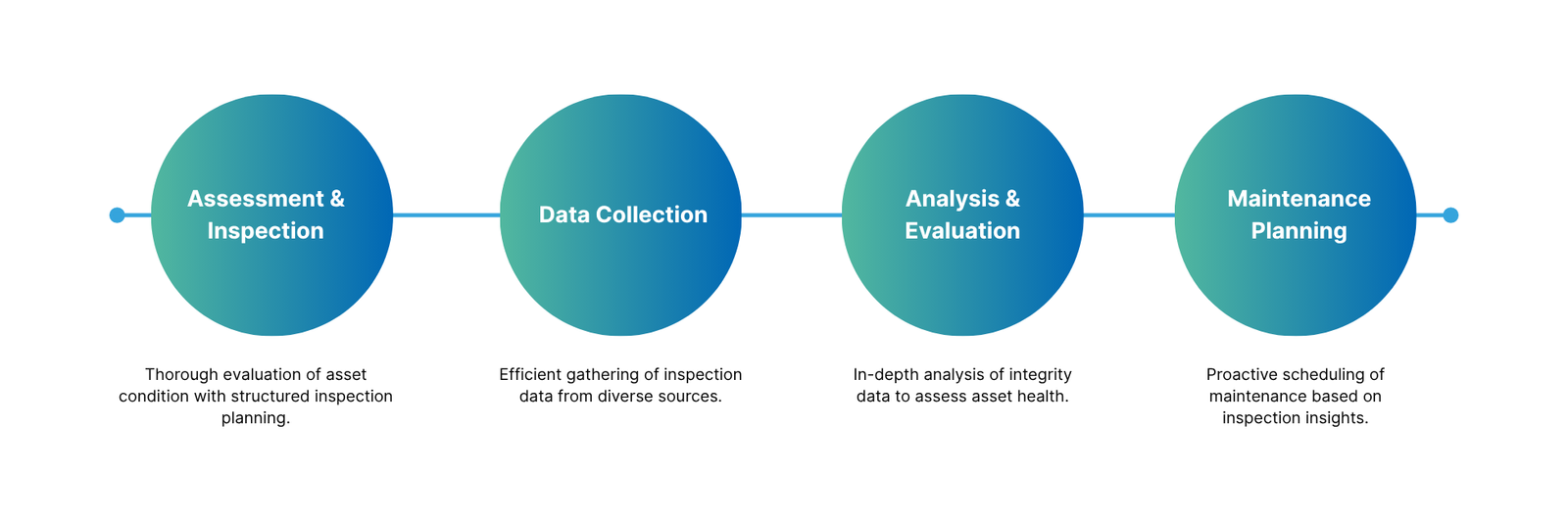

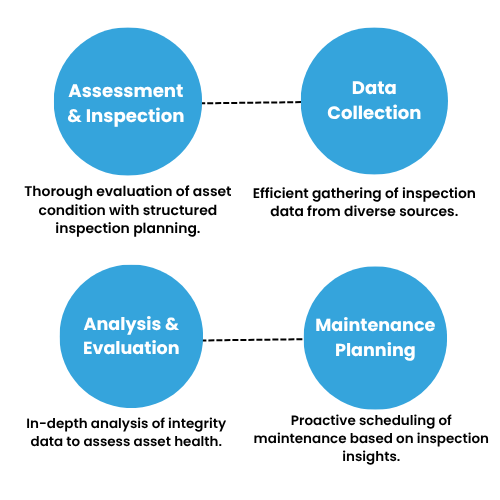

Asset Integrity Lifecycle

End-to-end management of every stage in the asset integrity process.

Enhanced Asset Management

State-of-the-art technology to optimize asset integrity.

Mechanical Integrity & Coating Manager

A next-generation solution for mechanical integrity and coating oversight. This advanced platform leverages AI-driven insights and robust data analytics to monitor and manage protective coatings on industrial assets.

CML Data Management

Capture CML readings on mobile devices with historical logging and trend analysis to improve corrosion control.

AI-Powered Recoating Forecast

Predict recoating schedules with AI based on corrosion data, environmental factors, and coating specs for optimized maintenance spend.

Patch & Repair Evaluation

Assess coating patch quality with AI-driven image analysis to ensure long-term asset integrity and verify repair quality.

Insulation & Fireproofing Planning

Plan and manage insulation and fireproofing projects across all service types and job complexities.

NACE-Compliant Surveys

Perform corrosion surveys with digital workflows fully compliant with NACE standards.

Mechanical Integrity & Coating Manager

Manage protective layers of industrial assets with AI insights and comprehensive data analysis for future-ready integrity management.

FAQ (Frequently Ask Questions)

Vibration, corrosion/UT, process data, and manual inspections are ingested and normalized into a common integrity data model.

Yes. Trend analysis and ML models forecast risks and propose next‑best actions for planners and inspectors.

CML setup supports historical logging and automated re‑inspection scheduling with route optimization.

Yes. Coating condition, patch QA, and recoating prediction are supported with linked photo evidence and notes.

Live policy checks, required evidence capture, and auto‑assembled audit‑ready reports ensure compliance.

Yes. API‑first integrations with Maximo, SAP, and others synchronize work orders and status.

Dashboards provide downtime and integrity KPIs, backlog health, and cost trend analytics.

Yes. Field capture works offline and synchronizes securely when connectivity returns.

Role‑based access control, multi‑step approvals, and tamper‑evident audit trails enforce governance.

Encryption at rest/in transit, RBAC, and hardened infrastructure protect sensitive data.